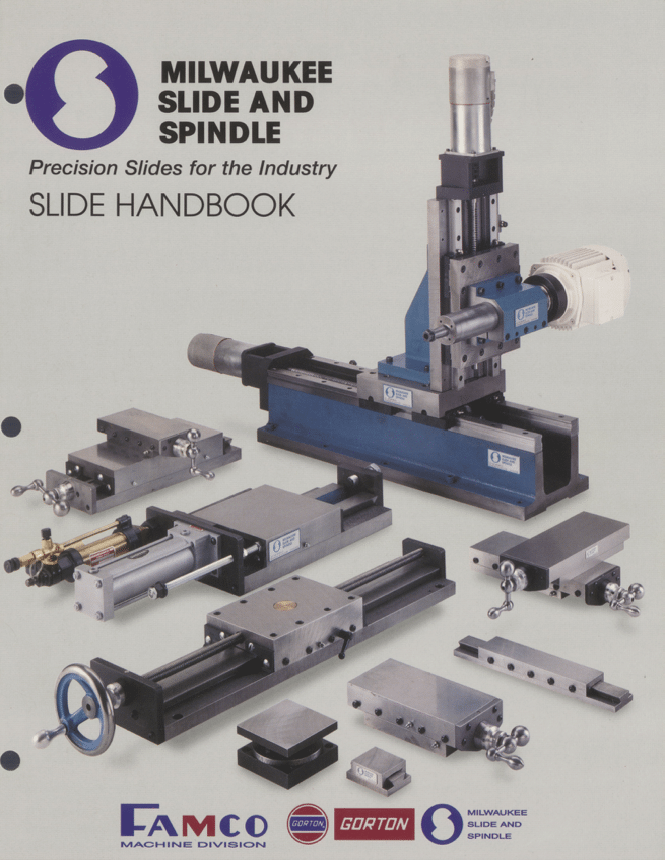

High-Quality Slides in Waukegan

Smooth Motion, Superior Performance

Experience smooth and precise motion with Famco's high-quality slides. Our slides are designed for reliability and efficiency in various industrial applications. Elevate your machinery performance with Famco's precision-engineered slides. Contact us today to learn more!

Milwaukee Precision Slides

Our slides are ready-made tracks that move on low friction or bearing ways to serve as motion guides for feeding and retracting parts, tools, or fixtures on all types of machinery. Each basic slide consists of a carrier and a base, both made of specialty-controlled cast iron, with precision-milled, ground dovetail or hardened steel ways fitted together with steel gib and gib screws for adjustment to ensure accurate movement. Milwaukee Precision Slides provide precise line movement, regardless of whether it is vertical or horizontal.

In the event that none of the standard slide assemblies illustrated on this web site will fill your specific needs, we suggest you tell us your particular problem. No matter how complex your needs for slide assemblies may be, our engineering department has experience with all types of slide applications in the modern machine tool industry. Their recommendations for the most economical assembly construction you can use are always available to you without obligation.

REGULAR DUTY BASIC STYLE

Standard Regular Duty MILWAUKEE SLIDE AND SPINDLE slides are useful for a broad range of applications where the load induced into the assembly is moderate and a compact design is essential. These basic-type slides, with easily adjustable gibs, insure accurate motion and offer a wide range of uses in the construction of automated machines. Regular Duty Basic slides can be supplied with reduced overall height to meet your applications or replacement needs.

These slide assemblies consist of a carrier, base, gib, and gib adjusting screws. They are available for design applications where the means for mounting, movement, and other requirements are provided by the customer.

REGULAR DUTY LEAD SCREW

These regular-duty screw-equipped slide assemblies are most useful where accurate manual positioning or feeding is required. Standard features are a precision lead screw, a graduated micrometer dial to indicate carrier movement and a balanced crank handle for ease in advancing and retracting the carrier or base. Knurled knobs are ideal for finer adjustment where space is limited.

AIR OR HYDRAULIC CYLINDER

These Regular Duty Cylinder powered slide assemblies are recommended both for quick-action movements and for repeatability, in tooling, fixturing, and parts positioning. Working pressures of 500 P.S.I. for hydraulic and 250 P.S.I. for air-operated cylinders. Double-acting, non-cushioned cylinders are standard. Special Cushioning and/or valving can be provided upon request.

AIR CYLINDER POWERED

Heavy Duty Air Cylinder Powered

Machine Slides with Hydraulic Check and Control Valves These heavy-duty machine slide assemblies are powered by the action of an air cylinder for rapid approach to the desired working range of the unit. The rate of approaching speed may be controlled with an easily installed control valve. Several types of valves for air cylinder control may be obtained. These cylinder-powered units are provided with hydraulic control. At the desired (pre-determined) phase or point of action, the hydraulic check valve can be set to control the rate of feed. Air cylinder source power for speed has greater advantages, whereas for a precise feed action, hydraulic non-compressible oil assures uniformity, accuracy and smoothness if needed.

Smooth and Precise Action

The extra-rigid base supports these controlling elements and assures the best possible smoothness and precise action over the entire working range.

HEAVY DUTY BASIC STYLE

Heavy Duty Basic slides are useful for a broad range of applications where the nature of the work to be done requires a more rugged construction than regular-duty assemblies. Greater stability and capacity are accomplished by the thickness of the carrier and base. The increased height of the carrier also allows greater flexibility for machining mounting requirements.

HEAVY DUTY RECESSED BASE

These slide assemblies feature versatility because of their availability in any incremental length. The recessed design in the base of the slide makes it possible to install a carrier drive inside the slide base. This permits a more compact design when mounting a ball screw and air or hydraulic cylinder rods. The cavity also reduces the weight of the assembly. Inquiries for special uses of power-driven recessed base-type slides are invited.

Flange Base

Heavy-duty recessed base machine slides are also available with a mounting flange. RBF-style slides are appropriate for many portable uses. They are available in the same sizes as RB slides.

HEAVY DUTY LEAD SCREW

Milwaukee Slide and Spindle, Heavy Duty Lead screw slide assemblies, with their rugged construction and extremely heavy sectional profiles, are most useful in precise movement and feeding mounted tools or fixtures into the working range. They assure the best possible slide positioning, freedom of movement under heavy loads, and moderate overhang with little, if any, deflection. These slide assemblies are available in a balanced crankhandle construction for control of slide movement by micrometer dial settings (assuring highly accurate positioning). For fine adjustment, a knurled knob component is available, which is very useful for conveniently adjusting to the desired settings.

RECESSED BASE LEAD SCREW

The MILWAUKEE SLIDE AND SPINDLE recessed base slide provides space for a lead screw having either a Vee or Acme thread on 4″ and 6″ slides. Acme is standard among the others. For higher loads and/or longer carrier travel, the Acme thread is recommended. Multiple carriers on one base that move either away or toward each other are possible by using a lead with R.H. and L.H. threads. Many other variations are also possible. Please consult our sales department for special applications.

IPM DOVETAIL SLIDES

IPM slide assemblies are versatile because of their availability in any inch increment of carrier and base length. This means the designer can use a slide to meet his specific length requirements, which often means a savings in cost and space.

Basic slide assemblies are manufactured with a longitudinal cavity in the base, permitting a more compact design when mounting the carrier drive. The cavity also reduces the weight of the assembly. In some applications, a base without the cavity may be advantageous because of the nature of the force applied or certain mounting requirements.

IPM bases 8–16 have cored pockets as standard to reduce weight. Gib lock handles provide an easy way to lock the carrier in a desired position. For convenience on all sizes, the lock handles may be adjusted to lock in different angular positions.

Surfaces can be supplied either milled, ground or scraped.

HARDENED WAY SLIDES

Construction Features

- Model 7-9-12-15-18-24 is 32 inches wide.

- 40,000 PSI Close-Grained Cast Iron Normalized.

- Casting lengths to 108 inches.

- Straight gibs are standard in carriers and keepers.

- Tapered gibs are available in carriers and keepers.

- Way wipers are standard accessories, while accordion way protectors are available as an option.

- Low-profile slides for special needs.

- Hardened Rails to 58/60 Rockwell C.

- Lubrication was provided to the necessary areas.

- Ball screws are available with assorted motor drives.

- Hydraulic Cylinders and Hydraulic Components Available: Limit Switches, Trip Pawls, Cam Rails, Decel and Speed Control Valves, etc.

- Large slide assemblies are inspected with lasers for precision.

- Engineering can be provided for all your custom needs: electrical, mechanical, Hydraulic and pneumatic.

- Non-galling, antifriction-bearing material (optional).

HARDENED STEEL WAYS

Including as Standard

- Gibs in keepers

- Way wipers

- Mounting holes in the base

- Lubrication for ways and drives

The carrier of fine grain provides high strength and minimizes distortion. This heavy, rugged base structure is designed to carry greater loads than conventional dovetail types. These slides can be fitted with JIC-mounted cylinder controls, flow control valves, adjustable positive stops, limit switches and trip pawls.

Any number of suitable saddle and base combinations are available to extend the range of application on this heavy load carrier slide in base lengths ranging up to a maximum of 108″.

This type of slide permits the installation of electric cycle controls and other optional auxiliary equipment. The open center structure in the base is suitable for lead screw or cylinder-powered operation.

RECIRCULATING BALL WAYS

Stay competitive in today’s dynamic manufacturing market with MILWAUKEE SLIDE AND SPINDLE Recirculation Ball Way Slides. These state-of-the-art slides and linear guideways will greatly improve your machine or system productivity.

MILWAUKEE SLIDE AND SPINDLE is a pioneer and leader in the research and development of high-efficiency machine tool slide assemblies. Our precision rails, with their rolling elements, utilize a new design that offers a more stable structure for withstanding moment loads. With this design, our Recirculating Ball Way Slides can deliver increased rigidity and stable high-speed travel. The older face-to-face concept would be hard-pressed to meet the machine tool rigidity of the empirical back-to-back design concept.

For applications requiring rigidity and precise, low-friction linear movement of heavy loads and movements, we offer standard models. Customized slides are also available.

The base and table are manufactured from high-tensile close-grain cast iron, normalized for maximum stability. Other materials are also available, such as steel, stainless steel and aluminum. The rolling elements and precision rails utilize MILWAUKEE SLIDE AND SPINDLE machine tool-quality bearing products.

All models are available with precision ground ball screws, keyed shaft extensions and a piloted mounting flange for power applications. Other types of drives or accessories similar to those used on dovetail and hardened steel way assemblies can be provided.

LOW PROFILE BALL SLIDE

Low-profile slide assemblies are useful for many service applications where accurate, high-speed positioning or feeding is needed.

These slide assemblies feature versatility because of their availability in any incremental length. The most significant advantage of these units is their load-carrying capacities, whereby the design loads can be applied in any direction to the table or base. All HUB assemblies are preloaded and specifically designed for vertical, inverted or horizontal applications.

We offer special tables or bases to meet customers’ particular requirements. The base of the table may be drilled, tapped and counterbored for mounting screws. The table surface may be machined to accept various accessories, fixtures and equipment.

The illustration shown is fitted with a preloaded, precision ground ball screw assembly.

HIGH PROFILE BALL SLIDE

HB-Deep base profile assemblies are designed to handle extra-heavy horizontal applications for special-purpose high-production machines.

The deep base model features a recess between the ways. With this clearance in the center of the base, feed mechanisms may be buried. Typical feed mechanisms might be rodless air cylinders, standard air or hydraulic cylinders, rack and pinion drives, special ball screws and position feedback equipment. Clearance ports can be provided through each side of the deep base model to allow easy access for plumbing or electrical wiring.

HB models carrying capacities range from 5,000 to 150,000 pounds; loads are assumed to be perpendicular and evenly spread over the table assembly. Loads may be applied in any direction to the table, but care must be taken to ensure that they are properly calculated. Special care should be taken with cantilevered loads.

The illustration shown is fitted with a preloaded precision ball screw assembly.

HBR-HBL-HBS BALL SLIDES

Alternative Profiles

The HBL, HBR and HBS have been the most popular of the various custom ball slides produced by MILWAUKEE SLIDE AND SPINDLE. Variations are available in widths from 6 inches to 60 inches and in lengths to suit your particular needs. For specific dimensions and loading characteristics, please consult our Applications Engineering Department.

HBL Ball Slide Assemblies are the most economical ball-way slides available with a lead screw drive. They can be furnished with the handcrank or motor of your choice.

HBR Ball Slide Assemblies are primarily for gantry-type machines and overhead robot arm applications.

HBS Ball Slide Assemblies are the MILWAUKEE SUPER SLIDE for extremely high moment loads. Axial load capacities can reach 1.5 million pounds of moment load.

MACHINE ANGEL PLATE

Standard Features

7 Size, 18 Models: Steel, Ground 90°, 2 Sides: Ground, Normalized and Sandblasted: The sides are ground and machined to 0.001″ perpendicularity.

SQUARE MACHINE SWIVELS

Standard Features

Base Mounting Holes: Low Carbon Steel; Top, Base, Clamp: Engraved Graduations – Swivel Table Top rotates on pivoting center bore at 360° graduated in 1° increments; Table Tops are ground and machined to 0.001; 4 clamp nuts lock swivel in place.

MACHINE TABLES AND BASES

Standard Features

11 Sizes, 19 Models, Rugged Welded Steel, Blanchard Ground Top Plate, Gray Enamel Paint

MANUFACTURING EXCELLENCE Since 1927

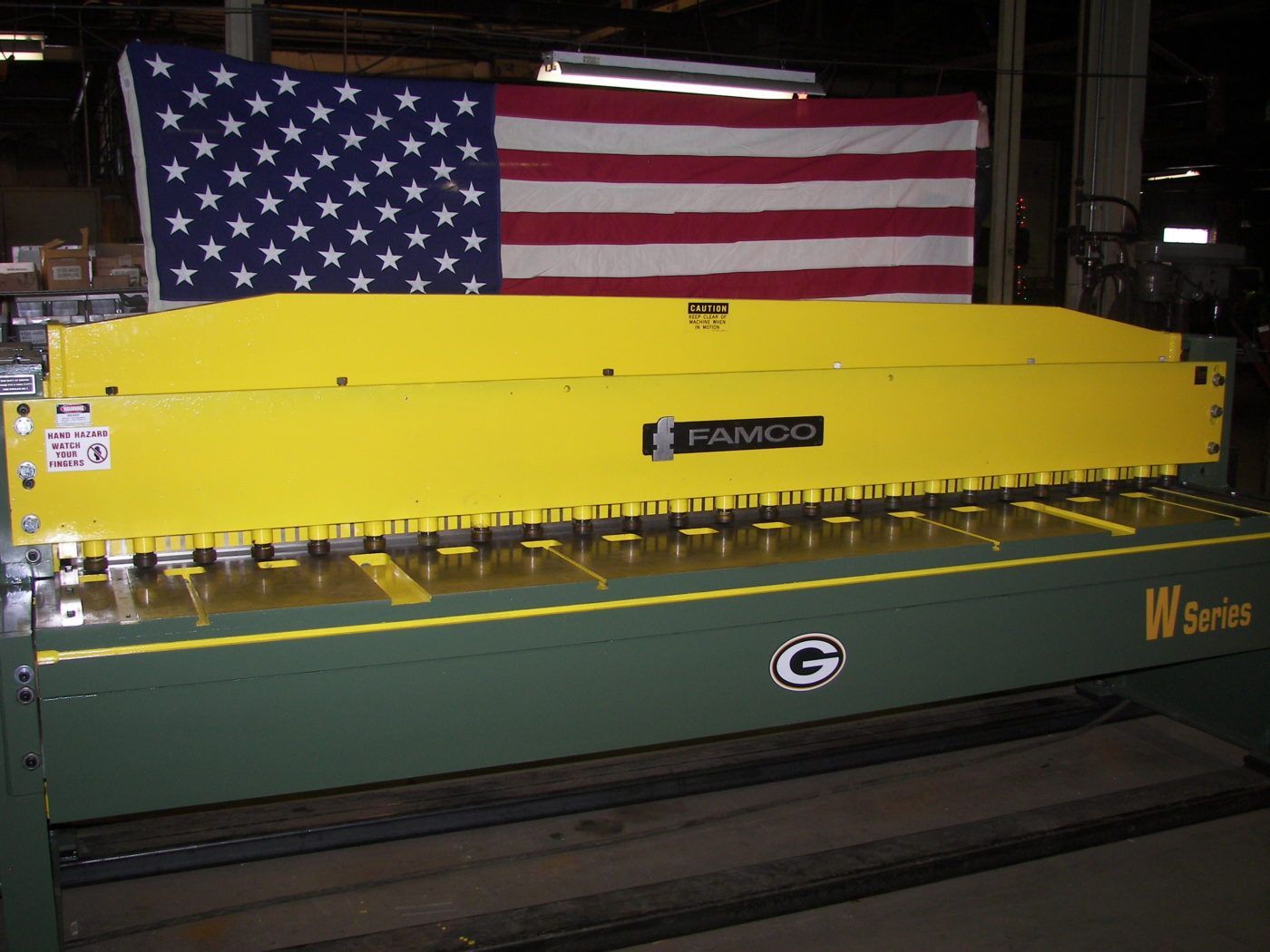

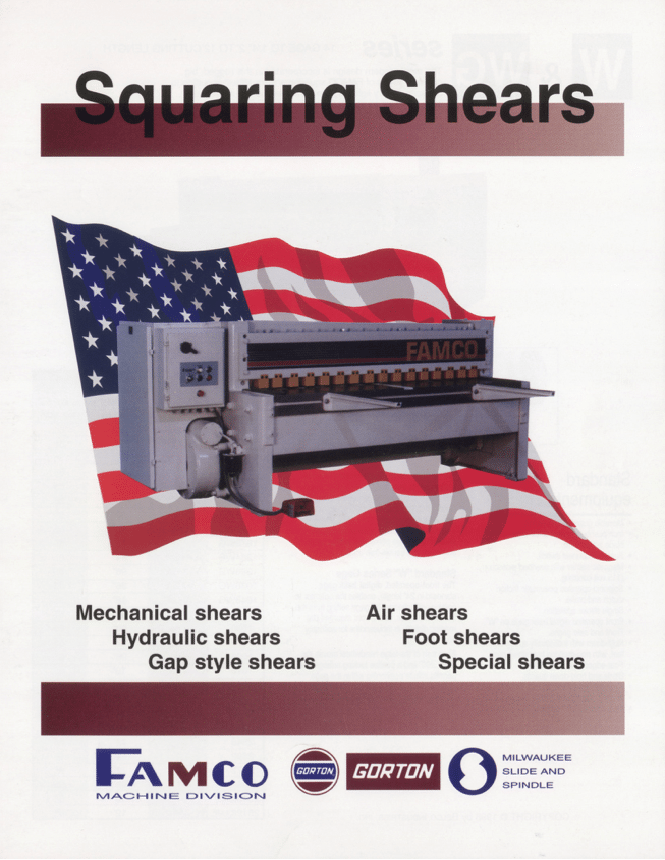

Famco is a leading manufacturer of mechanical shears for cutting metal, plastics, circuit boards, and other material types. Since 1975, Famco has been the preferred source for high-production mechanical, air, and hydraulic squaring shears.

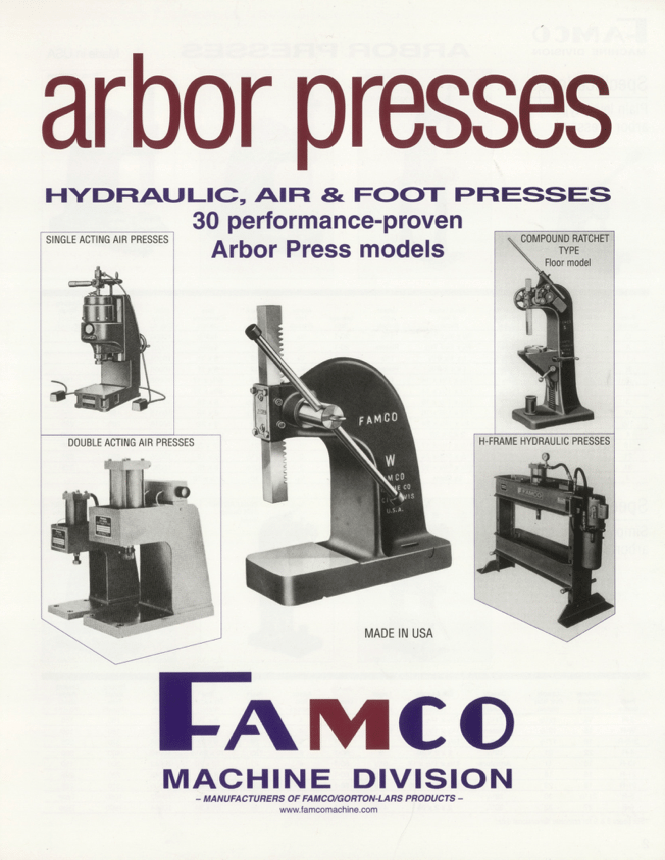

Since 1927, Famco has produced a variety of arbor, foot, and air presses. Famco is an American manufacturer of high-speed cut-to-length shears supplied to large OEM builders that are well known throughout North America and the world. Milwaukee Slide & Spindle is another product line that encompasses precision standard and special linear slide assemblies. The Gorton/Lars product line is supported by a limited offering of engraving cutters, character sets, machine belts, engraving and cutter grinding collets.

Master Craftsmanship in Shear Manufacturing: Famco's Legacy of Excellence

Famco stands out as a pioneer in the field of shear manufacturing, leveraging years of experience to produce top-tier mechanical shears for a diverse range of materials. Their expertise is showcased through their advanced mechanical, air, and hydraulic squaring shears, tailored for high-production environments. As a testament to their mastery, Famco's shears are renowned for their precision and durability, serving as the backbone for industries requiring meticulous cutting solutions.

REMANUFACTURE YOUR MACHINES TO NEW-MACHINE TOLERANCE

Famco Machine Division specializes in remanufacturing machines to new-machine tolerance standards. Each machine undergoes meticulous inspection of all components and parts, with damaged or excessively worn parts replaced as needed. Thorough reconditioning is conducted to restore optimal functionality. Following remanufacture, rigorous testing is performed to ensure compliance with new machine tolerances. Upon completion, the machine is restored to a like-new appearance and performance level, backed by a full one-year new machine warranty.

| Squaring Shears | Pantographs | Cutter Grinders | Machine Slides |

|---|---|---|---|

| “W” “WG” “B” Series — Mechanical Shears | 3U | 265 | All Types and Sizes |

| Hydraulic Shears | 3Z | 375 | |

| Air Shears | 3 | 500 | |

| P1-2 |

Take advantage of Our Specials and Save

Click the button for our specials on various Gorton copy sets and save money without compromising quality. See our other specials below.

Forging Innovation: Famco's History

In 1927, Mr. Herman Noll purchased the Freeze and Miller Company, forming his new corporation, Famco Machine Company. Since then, Famco has continued to be an American machine tool manufacturer of arbor, air, and foot presses, as well as power squaring shears. In 1975, the company was sold to Belco Industries, Inc. and continued to manufacture its former products under the Famco Machine Division banner.

In 1987, Famco acquired Gorton Machine Tool products along with Lars Corporation products and moved them to its newly expanded Kenosha facility. These products include the Gorton pantograph (engraving) line as well as the Lars tool and cutter grinders. In 1994, William Blasi purchased 100% of the assets of Famco Gorton/Lars. In 1996, Famco Machine Division and Belco Industries Incorporated acquired the assets of Milwaukee Slide and Spindle Company.

Famco is located on approximately 5 acres in Kenosha, Wisconsin. The current building is 55,000 square feet and is home to corporate offices, engineering, sales, manufacturing and purchasing.

The average length of Famco’s manufacturing personnel is approximately 20 years.

Famco's Superior Quality and Durability

Famco manufactures shears, slides, arbor presses, and Gordon Lars accessories. Each product line is manufactured here in Kenosha, Wisconsin, with more than 95% of its content made in America. A fact Famco is very proud of.

Famco has several types of shears in air, hydraulic, and mechanical formats. The mechanical line has the most variations, from geared-down models to high-speed production units. Famco is capable of customizing any of our standard shears to meet your needs. The Milwaukee Slide & Spindle has a multitude of standard slides. MSS produces both dovetail and linear ball guide slides. They can be driven with the standard Acme, V-Groove, or ball screws. Optional drive styles include hydraulic, pneumatic, and/or electric motors. MSS can create custom slides to match your needs too.

Famco arbor presses must be the world’s best arbor press just by looking at all the cheap imitations made of it. Famco produces both air and manual arbor presses. If Famco doesn’t have what you’re looking for, chances are it can still be made here. Just ask. While the Gorton Lars product line may have succumbed to the CNC age, Famco knows very well that there are still many in use today. That is why we still provide the more common accessories and replacement parts. So, don’t hesitate to call. You never know; Famco just may have the part you are looking for.

QUICK AND eASY RFQ Form

Ready to get started with Famco? Easily inquire about our available products through our convenient website form! Let us know what you're interested in, and our team will quickly provide all the details you need. Experience seamless communication as we tailor products to match your specific needs, making your decision-making process smooth and stress-free.

Precision on Every Page

Explore Famco's extensive product catalogs to discover a wide range of high-quality machinery solutions. From shears to slides, arbor presses, and accessories, our comprehensive catalogs showcase our commitment to precision and innovation.

What Our Satisfied Customers are Saying

"World renowned metal fabrication and machine shop"

Ekim B.

Slide title

"Needed a compound ratchet gear and pawl for a Famco 5C arbor press. Gentleman on the phone quickly identified part numbers and prices. Both parts were in stock. Prices were reasonable. Shipping was fast. Thank you"

Mike B.

Slide title

"Friendly employees"

Tanner M.

Why Choose Famco?

Count on Famco for high-quality slides. Our popularity as a renowned machine parts manufacturer is deeply ingrained in our unwavering commitment to excellence in slides. With a diverse range of products, including slides, remanufactured machines, and Gorton Lars accessories, all meticulously crafted in Kenosha, we have solidified our reputation as an industry leader in machine parts manufacturing. Known for our precision engineering and durable construction, our slides cater to various needs and applications. Whether it's customization options, superior craftsmanship, or reliable support for legacy machinery, we emerge as the preferred slides manufacturer for customers seeking top-tier machine parts solutions. Contact us today!

Frequently asked questions

Take a look at our most commonly asked questions for answers. Not seeing what you're looking for? Reach out to us for more information.

-

What services do you offer as a machine parts manufacturer?

In addition to supplying high-quality machine manufacturing, we also offer the following services:

- Shears

- Slides

- Presses

- Cutters

- Machine Slides

- Spindles

- Arbor Presses

Not seeing the service you're looking for or have additional questions? Call us, and one of our knowledgeable team members will be able to answer any questions!

-

What are your service areas?

Located in Kenosha, we serve the Chicago Metro including the following cities:

- Somers

- Pleasant Prairie

- Zion

- Racine

- Beach Park

- Salem

- Waukegan

- Gurnee

We Want to Hear About Your Needs

Fill out the form or call us at 262-654-3516. One of our knowledgeable team members will be able to assist you with all your machine parts manufacturing needs!

Slides

All Rights Reserved | Famco