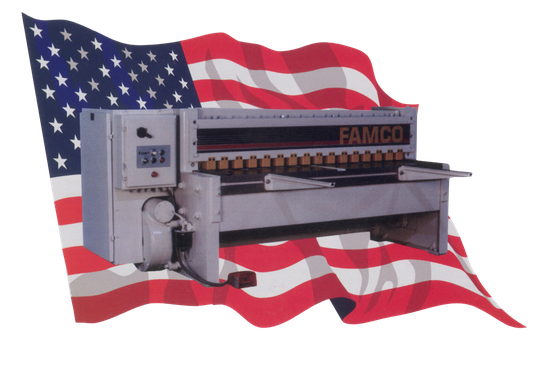

Enhancing Industries with Precision Shear Manufacturing

SHEAR Manufacturer in the SOUTHEAST WISCONSIN

MANUFACTURING EXCELLENCE Since 1927

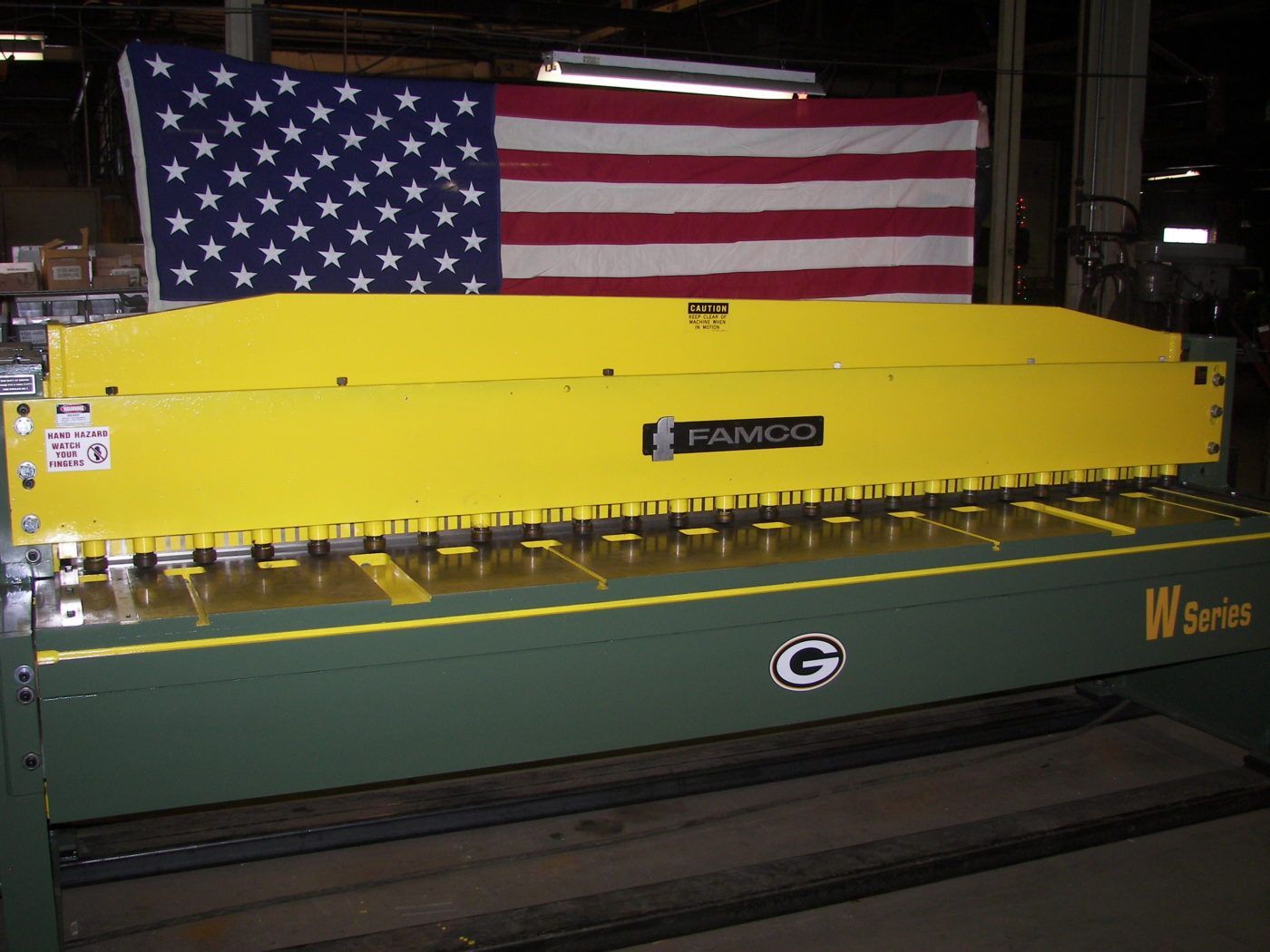

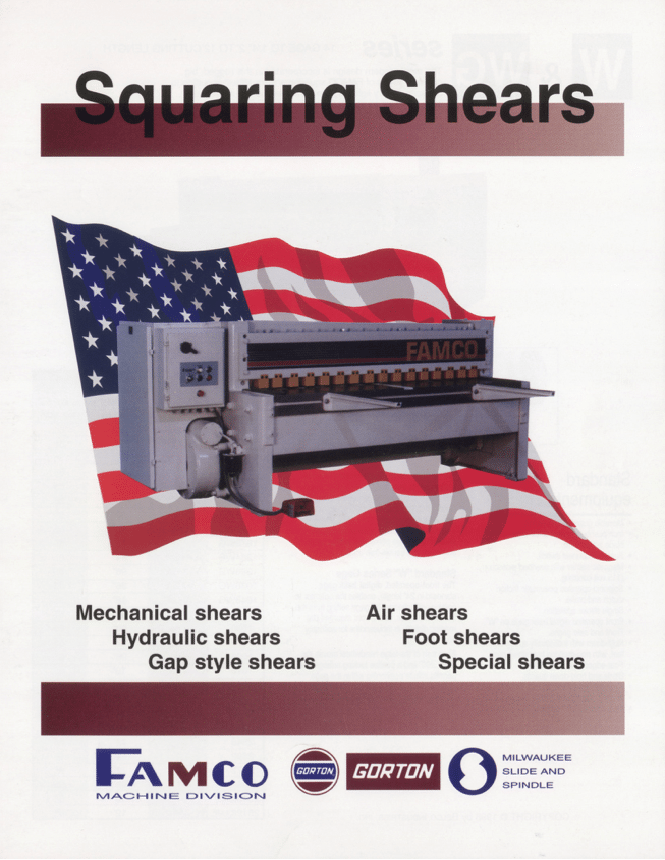

Famco is a leading manufacturer of mechanical shears for cutting metal, plastics, circuit boards, and other material types. Since 1975, Famco has been the preferred source for high-production mechanical, air, and hydraulic squaring shears.

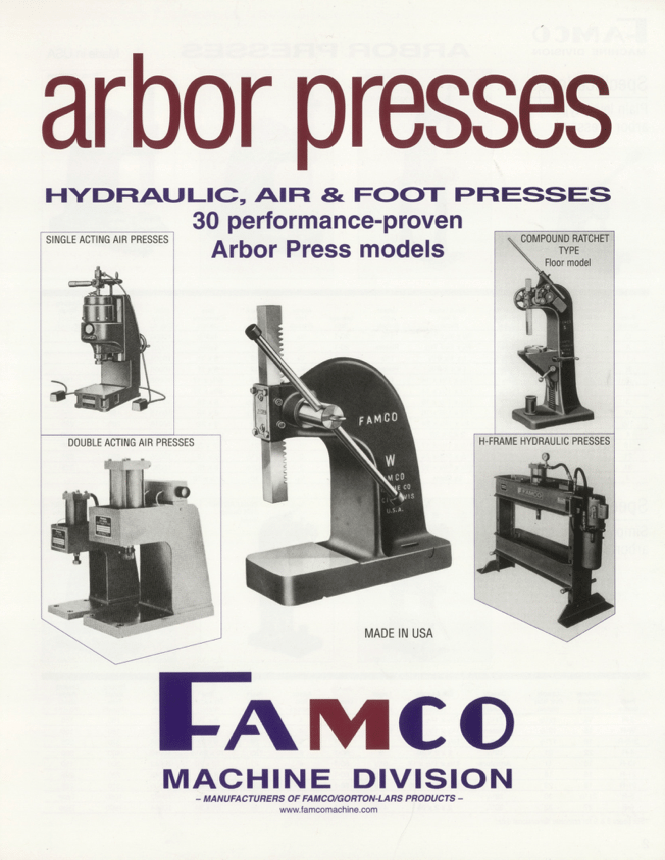

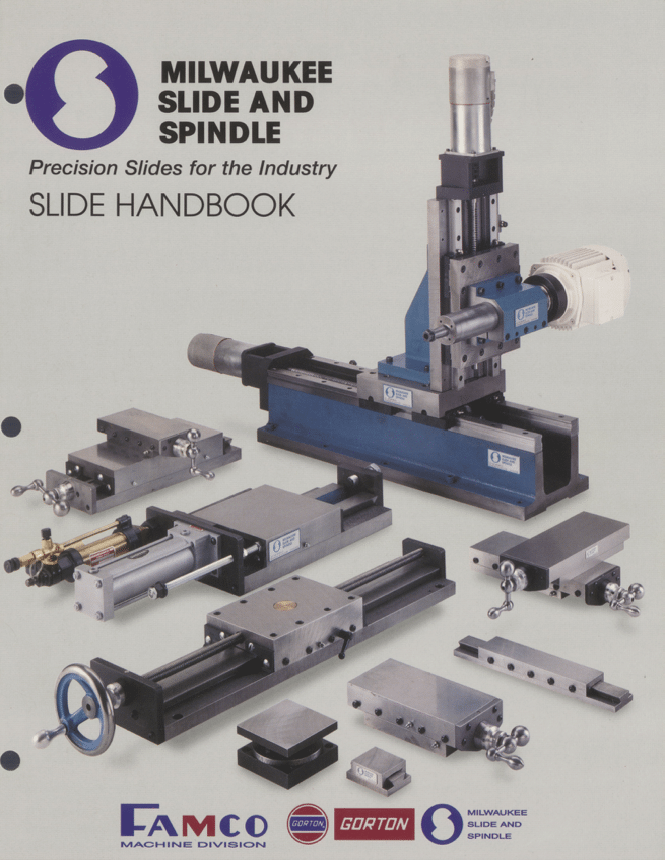

Since 1927, Famco has produced a variety of arbor, foot, and air presses. Famco is an American manufacturer of high-speed cut-to-length shears supplied to large OEM builders that are well-known throughout North America and the world. Milwaukee Slide & Spindle is another product line that encompasses precision standard and special linear slide assemblies. The Gorton/Lars product line is supported by a limited offering of engraving cutters, character sets, machine belts, engraving, and cutter grinding collets.

our Comprehensive Products

We offer products made to your specifications, not our specifications. Contact us today to place your order!

MASTER CRAFTSMANSHIP IN SHEAR MANUFACTURING: FAMCO'S LEGACY OF EXCELLENCE

Famco stands out as a pioneer in the field of shear manufacturing, leveraging years of experience to produce top-tier mechanical shears for a diverse range of materials. Their expertise is showcased through their advanced mechanical, air, and hydraulic squaring shears, tailored for high-production environments. As a testament to their mastery, Famco's shears are renowned for their precision and durability, serving as the backbone for industries requiring meticulous cutting solutions.

REMANUFACTURE YOUR MACHINES TO NEW-MACHINE TOLERANCE

Famco Machine Division specializes in remanufacturing machines to new-machine tolerance standards. Each machine undergoes a meticulous inspection of all components and parts, with damaged or excessively worn parts replaced as needed. Thorough reconditioning is conducted to restore optimal functionality. Following remanufacture, rigorous testing is performed to ensure compliance with new machine tolerances. Upon completion, the machine is restored to a like-new appearance and performance level, backed by a full one-year new machine warranty.

| Squaring Shears | Machine Slides |

|---|---|

| “W” “WG” “B” Series — Mechanical Shears | All Types and Sizes |

| Hydraulic Shears | Dove Tail |

| Air Shears | Ballway |

| Foot Shears | Hardenway |

Take advantage of Our Specials and Save

Click the button for our specials on various Gorton copy sets and save money without compromising quality. See our other specials below.

Forging Innovation: Famco's History

In 1927, Mr. Herman Noll purchased the Freeze and Miller Company, forming his new corporation, Famco Machine Company. Since then, Famco has continued to be an American machine tool manufacturer of arbor, air, and foot presses, as well as power squaring shears. In 1975, the company was sold to Belco Industries, Inc. and it continued to manufacture its former products under the Famco Machine Division banner.

In 1987, Famco acquired Gorton Machine Tool products along with Lars Corporation products and moved them to its newly expanded Kenosha facility. These products include the Gorton pantograph (engraving) line as well as the Lars tool and cutter grinders. In 1994, William Blasi purchased 100% of the assets of Famco Gorton/Lars. In 1996, Famco Machine Division and Belco Industries Incorporated acquired the assets of Milwaukee Slide and Spindle Company.

Famco is located on approximately 5 acres in Kenosha, Wisconsin. The current building is 55,000 square feet and is home to corporate offices, engineering, sales, manufacturing and purchasing.

The average length of Famco’s manufacturing personnel is approximately 20 years.

Famco's Superior Quality and Durability

Famco manufactures shears, slides, arbor presses, and Gordon Lars accessories. Each product line is manufactured here in Kenosha, Wisconsin, with more than 95% of its content made in America. A fact Famco is very proud of.

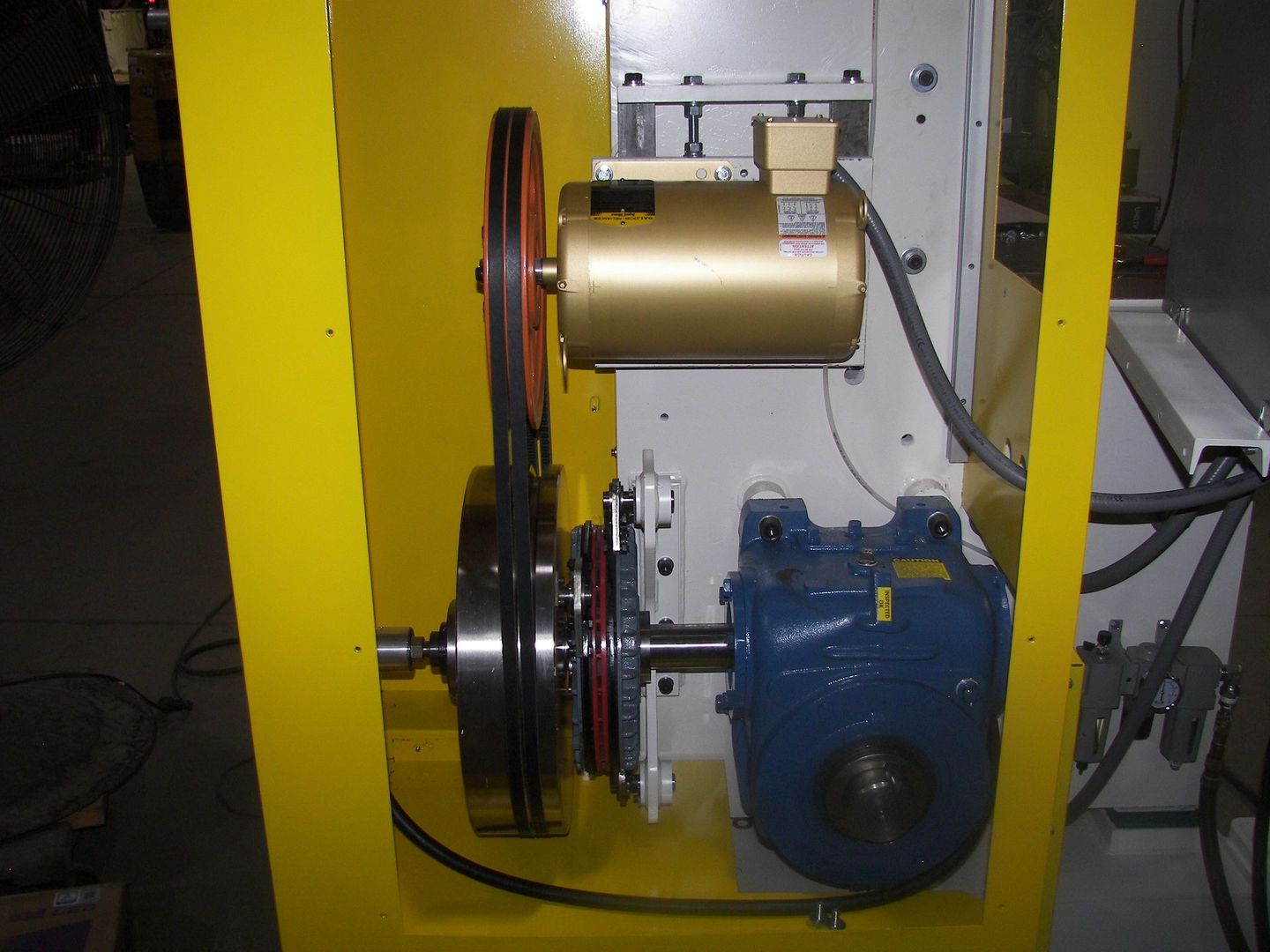

Famco has several types of shears in air, hydraulic, and mechanical formats. The mechanical line has the most variations, from geared-down models to high-speed production units. Famco is capable of customizing any of our standard shears to meet your needs. The Milwaukee Slide & Spindle has a multitude of standard slides. MSS produces both dovetail and linear ball guide slides. They can be driven with the standard Acme, V-Groove, or ball screws. Optional drive styles include hydraulic, pneumatic, and/or electric motors. MSS can create custom slides to match your needs too.

Famco arbor presses must be the world’s best arbor presses just by looking at all the cheap imitations made of them. Famco produces both air and manual arbor presses. If Famco doesn’t have what you’re looking for, chances are it can still be made here. Just ask. While the Gorton Lars product line may have succumbed to the CNC age, Famco knows very well that there are still many in use today. That is why we still provide the more common accessories and replacement parts. So, don’t hesitate to call. You never know; Famco just may have the part you are looking for.

QUICK AND eASY RFQ Form

Ready to get started with Famco? Easily inquire about our available products through our convenient website form! Let us know what you're interested in, and our team will quickly provide all the details you need. Experience seamless communication as we tailor products to match your specific needs, making your decision-making process smooth and stress-free.

Frequently asked questions

Take a look at our most commonly asked questions for answers. Not seeing what you're looking for? Reach out to us for more information.

We Want to Hear About Your Needs

Fill out the form or call us at 262-654-3516. One of our knowledgeable team members will be able to assist you with all your machine part manufacturing needs!